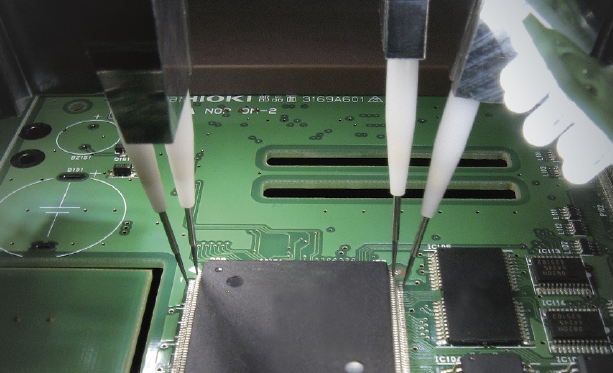

Electrical Testing Verifies Correct Mounting

Create a program from the design data, perform electrical testing with minimal time and cost, and quickly confirm and record defects.

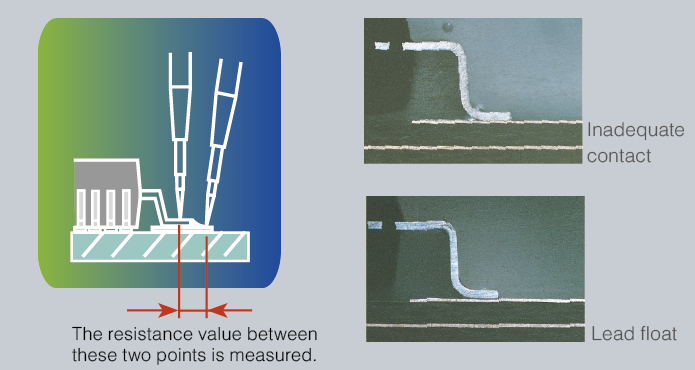

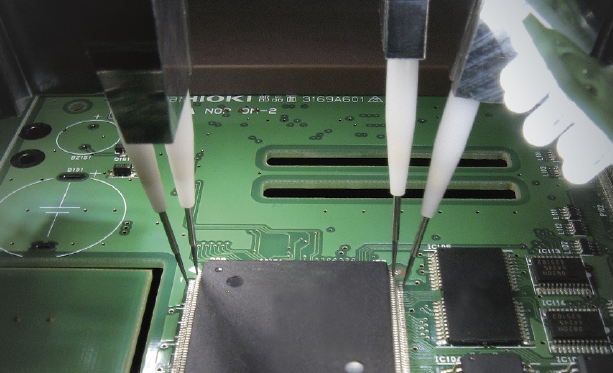

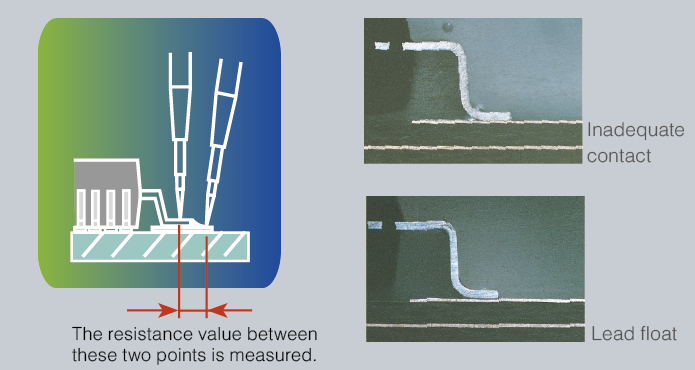

Lead float and pseudo-contact are not the same thing.

Pseudo-contact of leads is a type of defect that may slip through various tests during the board manufacturing process and make its way into the market.

Lead float can be fairly reliably identified by today's image inspection technology.Consequently, Hioki's proprietary resistance measurement pseudo-contact test serves to detect pseudo-contact, which is difficult to identify based on appearance alone.

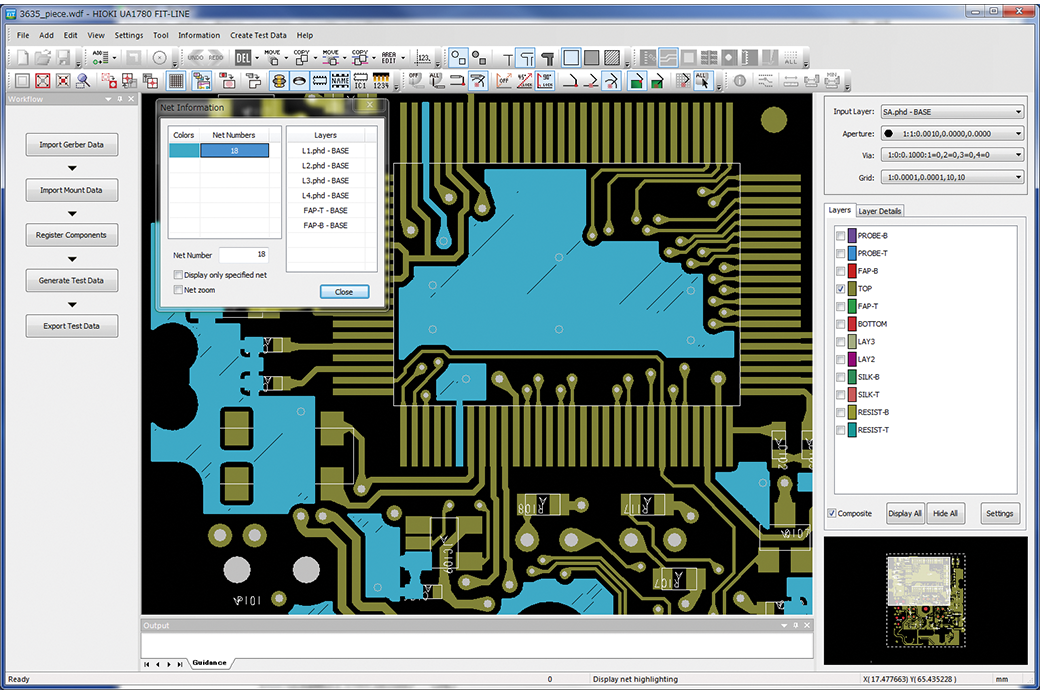

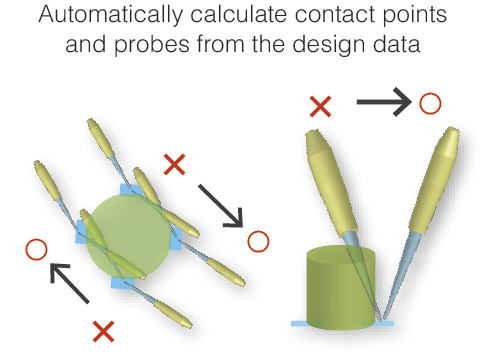

Focusing on the supreme importance of test points and Gerber data

It's half true, and half untrue, to say that the ability to easily create data is distinct from the ability to easily test boards.Being able to create data easily may have meant being able to test boards easily during the discrete era, but in creating the test data required by the FA1240, it is critical that creating accurate test data be a simple and easy-to-perform process.

By minimizing the difference between data that's good enough to operate the tester and data that's good enough to ship products, it is possible to minimize production line downtime (to allow for debugging and other modifications) and to ship products with peace of mind.

Simply follow the workflow.

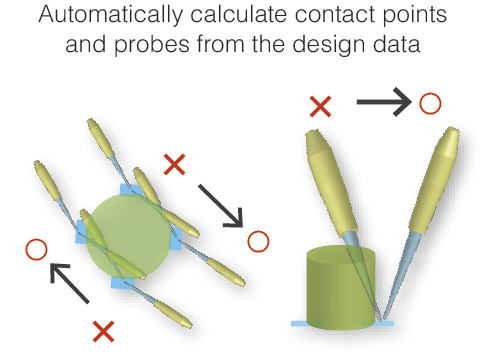

Quickly complete programs that take into account component height

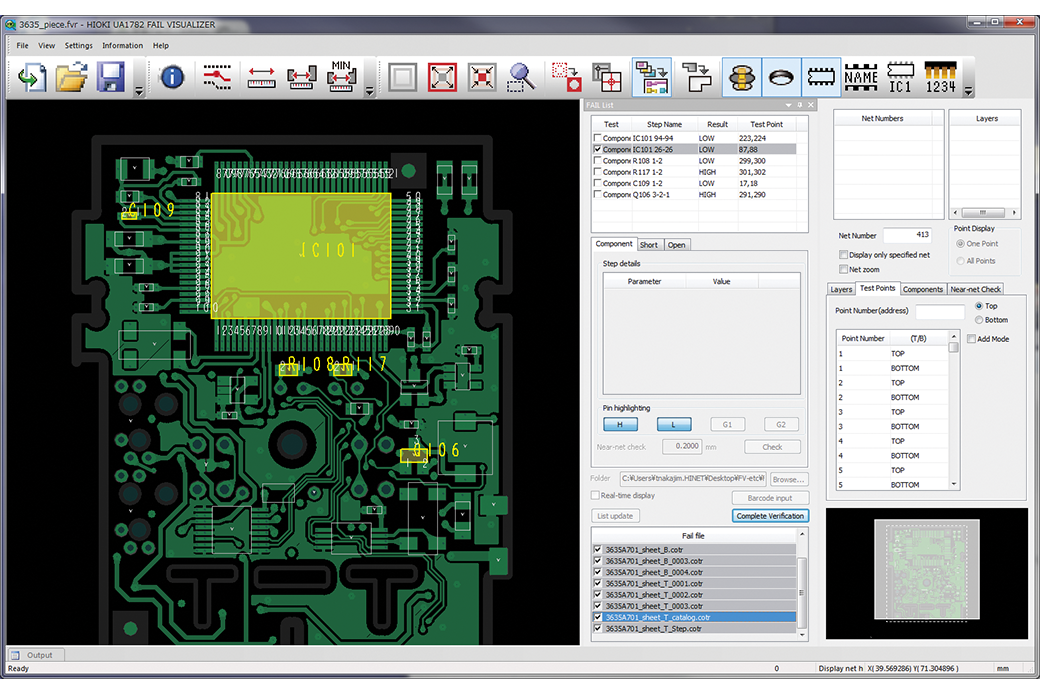

Automatic calculation of arm interference (when used with the UA1780)

Do you check data by looking at probe tips and asking yourself whether they'll strike components on the board or not?

In fact, choosing probes used to be a demanding and time-consuming part of the debugging process that required a high degree of care.By adding component height information to mounting data, the FA1240 is able to automatically select an appropriate test probe, allowing you to approach the task of debugging electrical testing with peace of mind.

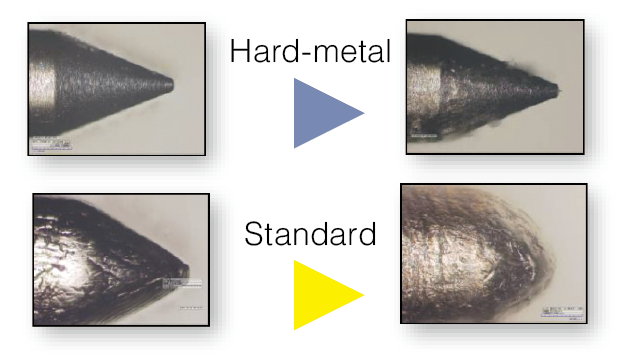

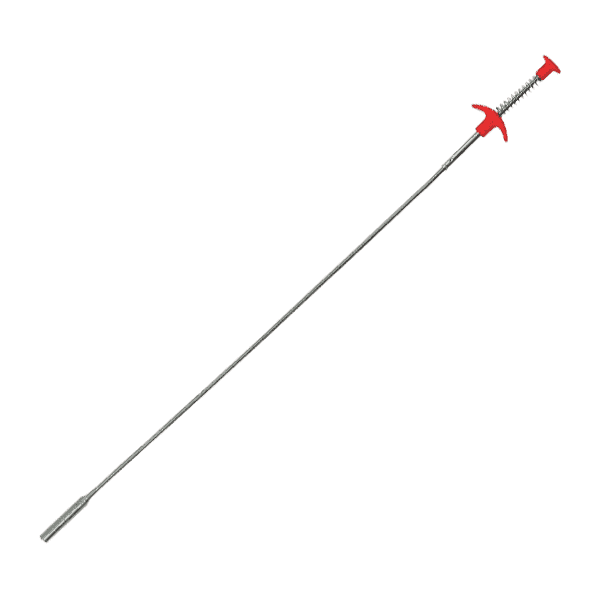

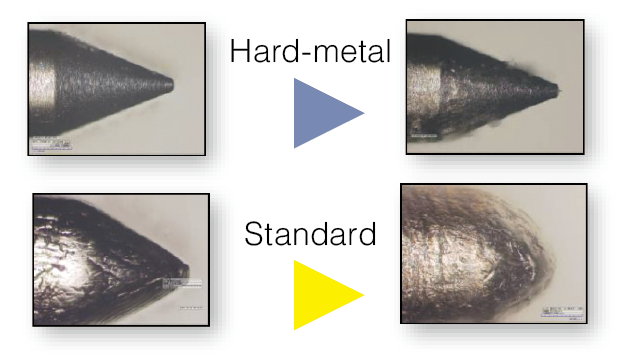

Long-life probes (easy replacement NEW and long service life)

The tips of Hioki's new super-hard probes show no wear, even after 3 million contact cycles.

Stable contact for up to 3,000,000 uses, prevents pseudo-contact due to slips

Calibration

Calibration

HVAC/Clean Rooms

HVAC/Clean Rooms

Electrical

Electrical

Temperature

Power & Energy

Power & Energy

Mechanical & Maintenance

Mechanical & Maintenance

Pharma, Health & Biomedical

Pharma, Health & Biomedical

Drone Solution

Drone Solution

Networking

Networking

Transformer & Relay Testing

Transformer & Relay Testing

Insulation, Resistance and Battery

Insulation, Resistance and Battery

Fault Testing & Diagnostics

Fault Testing & Diagnostics

Lightning Protection Solution

Lightning Protection Solution

Education, Research & Development

Education, Research & Development

Civil Equipment

Civil Equipment

Renewable Energy

Renewable Energy

Cleaning and supplies

Cleaning and supplies

Power Tools

Power Tools

Safety Tools

Safety Tools

Hardwares

Hardwares

Construction Supply

Construction Supply

Stationeries

Stationeries

Garden Tools

Garden Tools

Accessories

Accessories

Machines

Machines

Hand Tools

Hand Tools