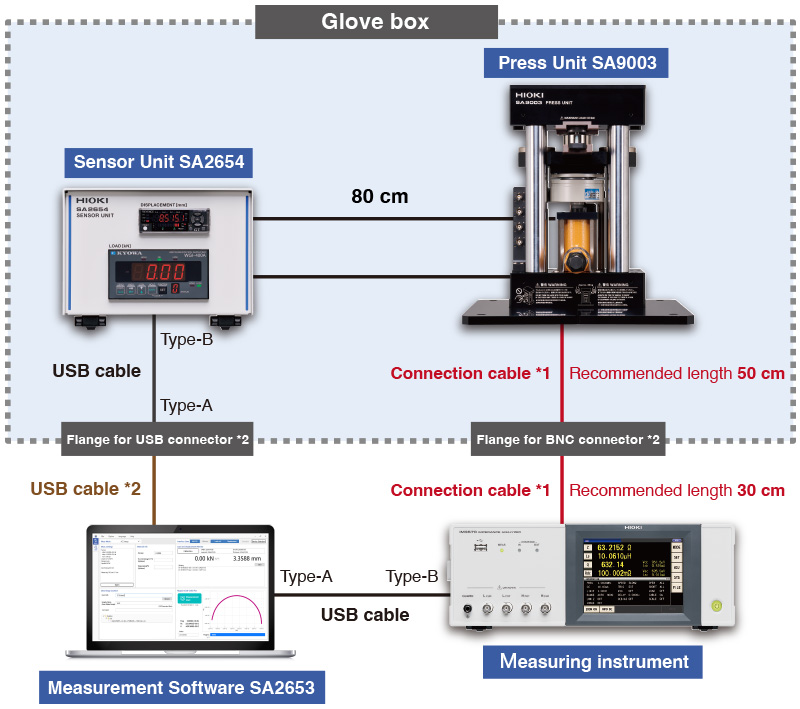

System configuration

Proper evaluation of the mechanical and electrical properties of powder materials

To properly evaluate the mechanical and electrical properties of powder materials, all mechanisms and software are designed in-house at Hioki.

- Measurement software that integrates the measurement data

- Sensor unit that monitors pressure and displacement

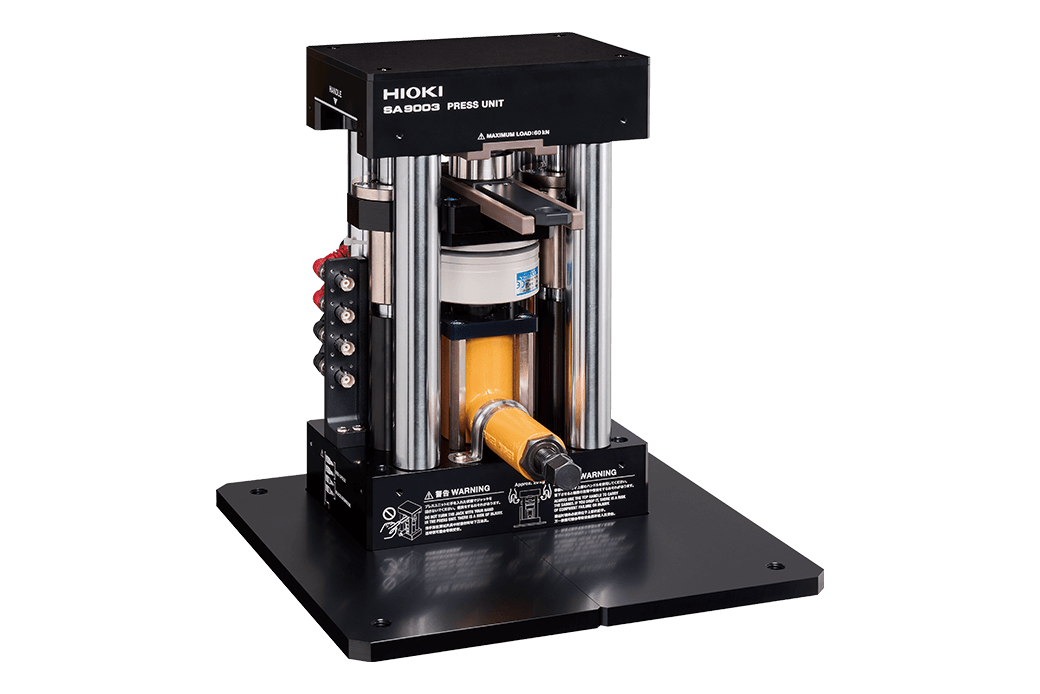

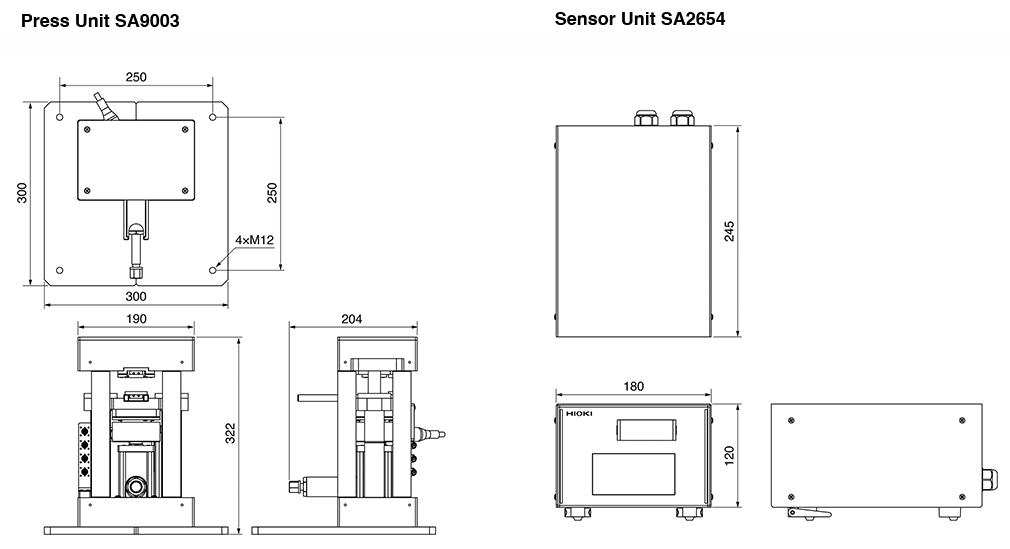

- Compact press unit with a built-in pressing mechanism, load cell, and displacement gauge

- High-intensity test fixture for filling powder materials

- Mold release unit for removing the pressed powder

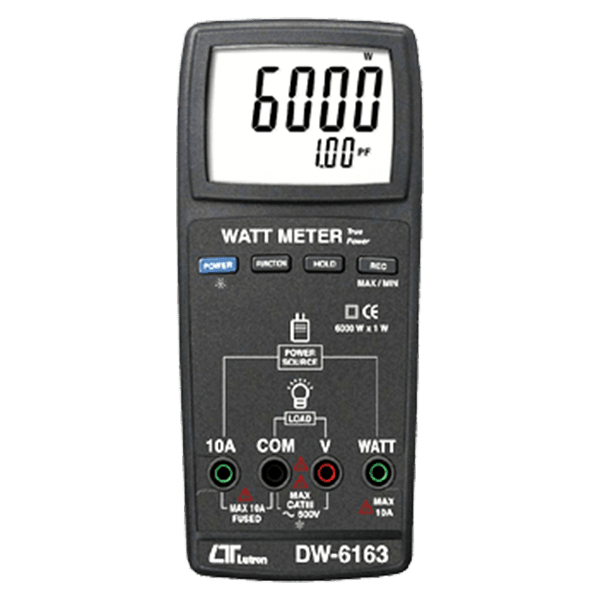

Depending on the measurement target, you can select either AC resistance measurement or DC resistance measurement supported instruments:

- Solid electrolytes -> AC resistance measurement

- Conductive auxiliaries -> DC resistance measurement

By combining three types of measuring instruments, the system covers a wide measurement frequency range of DC, 1 mHz to 5 MHz.

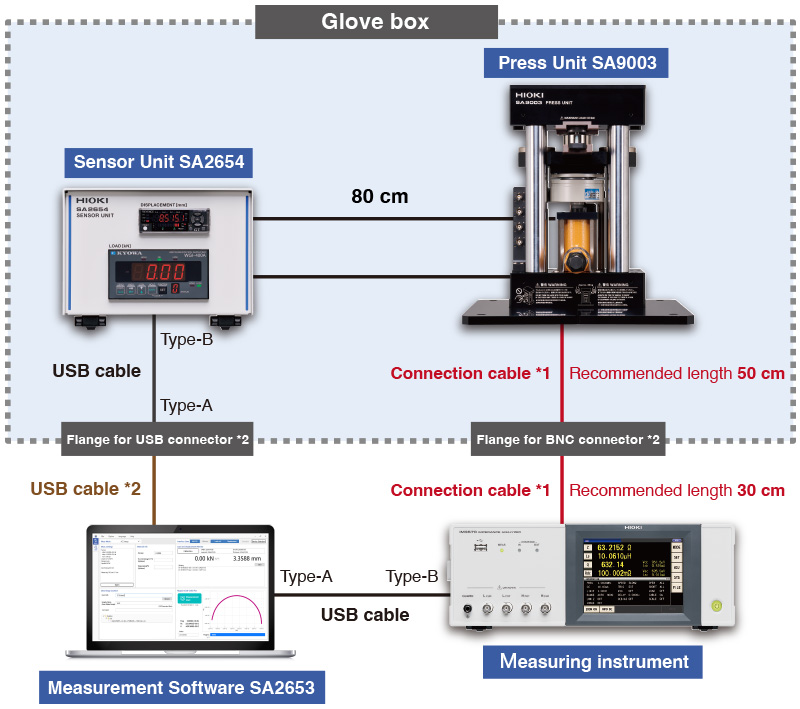

All-in-one glove box operation

The compact-size SA9003 Press Unit allows it to be installed inside the glove box. This enables the entire process, from material loading to powder pressing and measurement, all tasks to be completed safely inside the glove box. For dimensions, please refer to the specifications.

The length of the connection cable between the SA9003 Press Unit and the measuring instrument is 80 cm.

(30 cm between the measuring instrument and BNC flange, and 50 cm between the BNC flange and press unit)

Two USB cables (A-B type) are included as accessories with the system.

For more details, please contact your distributor.

Notes in the figure

- *1:Custom orders are available.

- *2:Please prepare it yourself or consult your distributor.

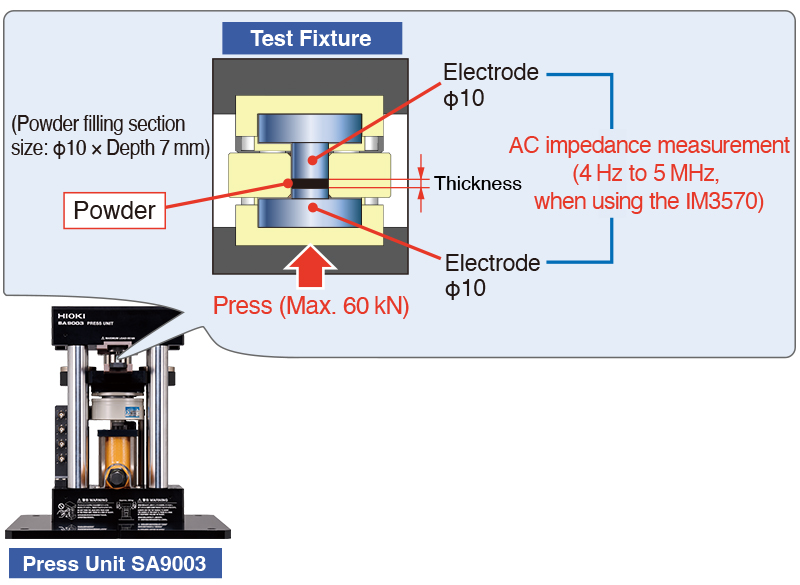

Measuring principle

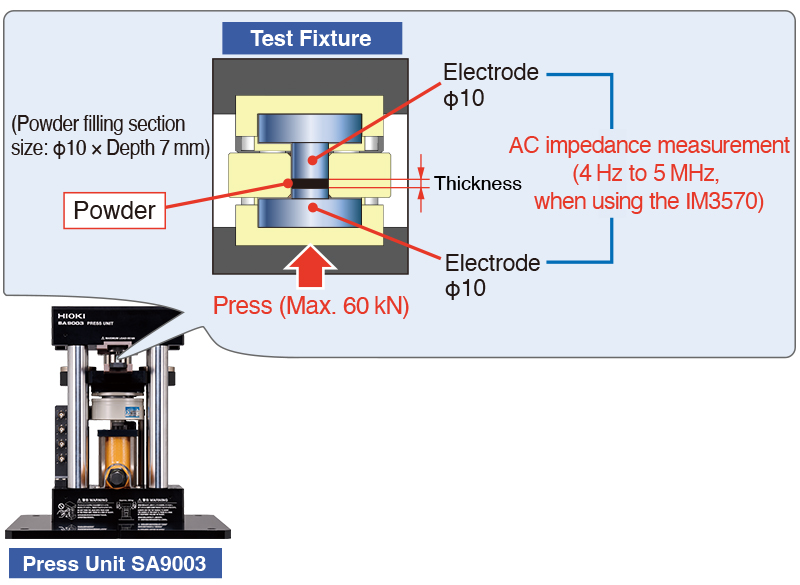

How the measurement works

The impedance measurement method of this system is the 2-terminal method.

AC impedance measurements are conducted between electrodes with a diameter of 10 mm, placed above and below the powder.

Since the electrode is also subjected to high-pressure, they are made of a high-intensity cemented carbide, which is also used in powder molding.

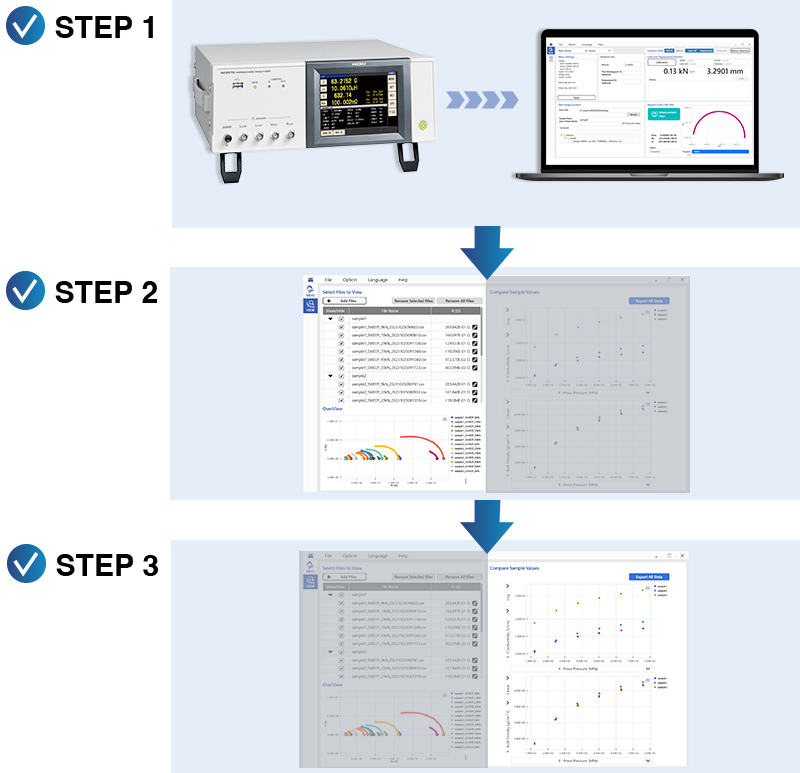

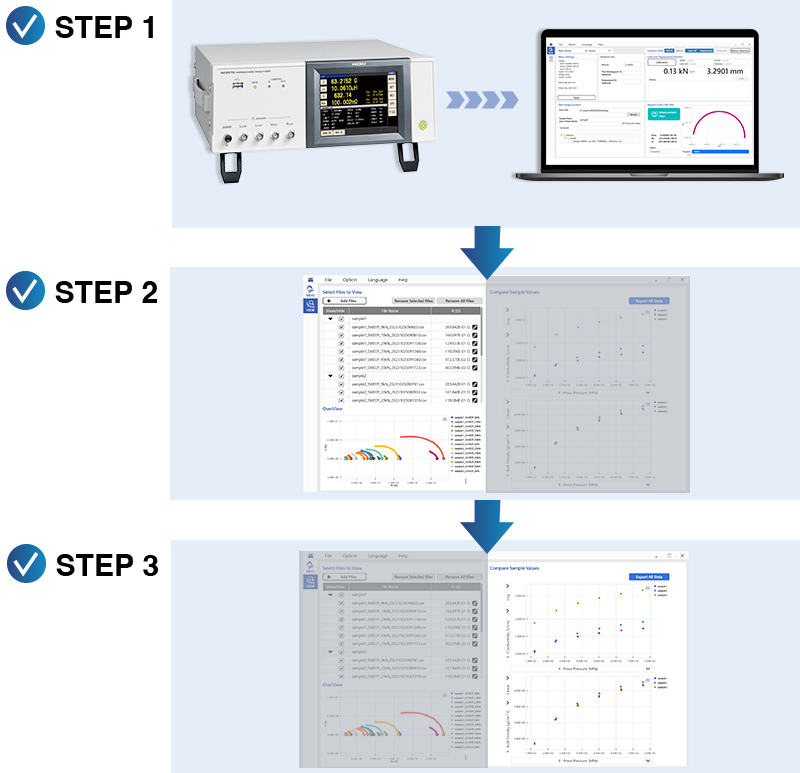

Graphing capabilities

Visualize results with built-in graphing functions for in-depth analysis

The dedicated software includes both measurement function and Viewer function.

Therefore, you can instantly compare data between samples once the measurement is complete.

STEP 1: Simultaneously acquire impedance, thickness, and pressure data.

STEP 2: Calculate the overall resistance from the measured impedance data. Based on the overall resistance, ionic conductivity, conductivity, and volume resistivity are calculated.

STEP 3: Using the Viewer function, you can create graphs for any selected parameters and compare data between samples.

| X-axis |

Load (kN), pressure (MPa), bulk density (g/cm3), filling factor (%) *3, porosity (%) *3 |

| Y-axis |

Impedance (Ω), volume resistivity (Ωcm), conductivity (s/cm), ionic conductivity (s/cm), relative permittivity (F/m) *4, bulk density (g/cm3), thickness (mm), filling factor (%) *3, porosity (%) *3 |

- *3:Only when the true density is entered.

- *4:Only for specific frequency measured in AC Continuous mode.

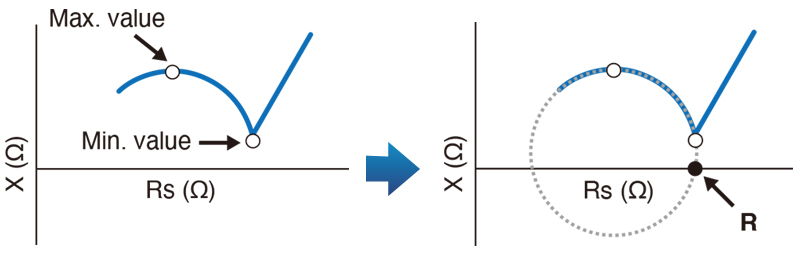

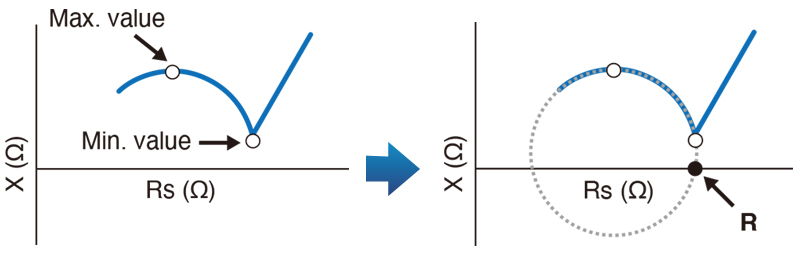

Automatic calculations: Easily calculate overall resistance (R) with Nyquist plot fitting

The maximum and minimum X (Ω) values are automatically extracted from the arcs of the Nyquist plot.

Circle fitting is performed on the data between the extracted maximum and minimum values, and the intersection with the X-axis is used to determine the overall resistance value R.

Calibration

Calibration

HVAC/Clean Rooms

HVAC/Clean Rooms

Electrical

Electrical

Temperature

Power & Energy

Power & Energy

Mechanical & Maintenance

Mechanical & Maintenance

Pharma, Health & Biomedical

Pharma, Health & Biomedical

Drone Solution

Drone Solution

Networking

Networking

Transformer & Relay Testing

Transformer & Relay Testing

Insulation, Resistance and Battery

Insulation, Resistance and Battery

Fault Testing & Diagnostics

Fault Testing & Diagnostics

Lightning Protection Solution

Lightning Protection Solution

Education, Research & Development

Education, Research & Development

Civil Equipment

Civil Equipment

Renewable Energy

Renewable Energy

Cleaning and supplies

Cleaning and supplies

Power Tools

Power Tools

Safety Tools

Safety Tools

Hardwares

Hardwares

Construction Supply

Construction Supply

Stationeries

Stationeries

Garden Tools

Garden Tools

Accessories

Accessories

Machines

Machines

Hand Tools

Hand Tools