Electrical safety in the factory is not only a matter of legal obligation; it is closely related to the lives of employees and the financial security of the organization. The electrical system of a factory is complex and extensive, involving numerous machines, motors, control panels, and power units. Due to inefficiency, faulty equipment, or lack of timely testing, even a small electrical problem can turn into a major accident. But with the help of digital measuring instruments, these risks can be easily identified, analyzed, and resolved. Below are some modern and effective digital measuring instruments that are very necessary to ensure the electrical safety of the factory.

Digital Multimeter

A digital multimeter is a versatile measuring instrument used to measure various values in electrical circuits, such as voltage (AC/DC), current, resistance, capacitance, frequency, etc. This instrument is unparalleled in diagnosing any power supply problem, wire disconnection, short circuit, or voltage fluctuation. From the main panel of the factory to the small control boxes, a multimeter is needed in almost every place.

A good quality multimeter can safely test live wires. It helps technicians identify problems in a short time. Nowadays, many multimeters have auto-ranging, backlit displays, audio alarms, and True-RMS technology, which ensures more accurate measurements. Multimeters have become essential for checking the voltage value of the line while turning on or off various equipment every day in the factory.

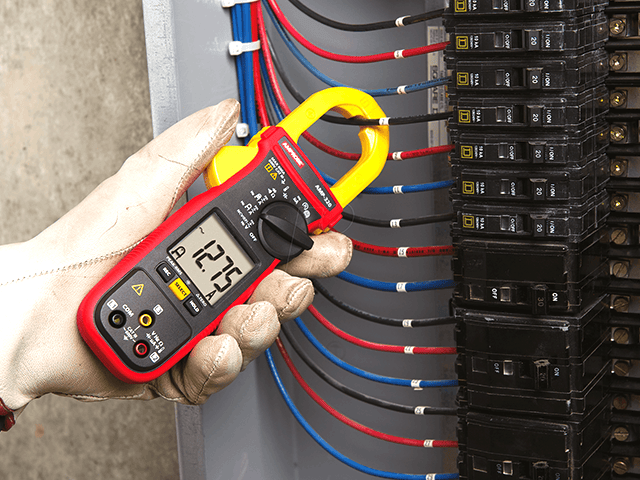

Use of Clamp Meter

A clamp meter is a digital instrument used for measuring current. It is designed in such a way that the current value can be measured by simply placing a clamp around the wire without directly connecting it to any other wire. This provides a great safety advantage while working on power lines. Sometimes disconnecting a live cable is risky and time-consuming, so current can be easily measured with the help of this instrument.

Modern clamp meters have the facility to measure voltage, resistance, and frequency in addition to AC/DC. Some models also have a memory function, min/max value, and hold option. It is also used in automation systems where the total current draw of the equipment can be analyzed to understand which equipment is taking an extra load. As a result, it is possible to reduce the risk of accidents by taking timely action.

Insulation Resistance Tester

An insulation tester or megger is essential for the electrical safety of a factory. If the insulation between electrical wires, cables, control panels, or motors is weak or damaged, it can cause serious accidents like fire through a short circuit or a spark. An insulation tester can be used to check insulation resistance at different voltage levels.

Advanced insulation testers provide features such as various test modes, such as PI (Polarization Index), Di-electric Absorption Ratio, etc., which provide detailed information about the condition of the insulation. During the maintenance of each wire or motor, the insulation should be checked with this device to verify its suitability for use.

Power Analyzer

The power analyzer is very effective for a complete analysis of the factory's power system. This device can monitor current, voltage, power factor, apparent power (kVA), real power (kW), reactive power (kVAR), harmonic distortion, etc. It is generally used in places where the performance of large motors, generators, or load systems has to be analyzed.

Harmonic distortion reduces the life of the equipment and causes excessive heat. The power analyzer detects these and warns. It also plays an important role in load balancing, system optimization, and energy saving.

Thermal Imager

Thermal imager or infrared camera is a modern device that takes temperature-based images and identifies hot spots in the factory's electrical devices. Loose connections, overloads or short circuits in electrical connections can cause abnormal temperature increases. Those hot areas can be identified at a glance with a thermal imager.

Regular inspections using this device catch unseen problems in time. This not only protects the equipment, but also maintains a safe working environment. Many advanced thermal imagers can be connected to video recording and analysis software, which helps in creating more effective reports.

Modern Solutions in Light Measurement and Ensuring Safety

A lux meter is a digital device that is used to measure light or light level at a specific location. In industrial establishments, factories, laboratories, or offices, the presence of proper light is very important for safety, productivity, and efficiency. Just as proper light is needed for human eye comfort, the performance of equipment often depends on the presence of appropriate light. An adequate and balanced lighting environment is essential, especially for those who work with delicate parts. A lux meter can easily determine whether the amount of light in a location is less than or more than the ideal value (Lux Value).

A lux meter works through a light sensor, which measures the amount of light and displays it in the form of a digital reading. Many advanced models have measurements in different units, range selection, memory function, and alarm settings. If there is a lack of light, the eye strain of the workers increases, the error rate increases, and the safety risk also increases. For example, in insufficient lighting, workers can bump into machinery while walking or operate switches or electrical appliances incorrectly, which can lead to major accidents.

As a result, proper lighting planning can be done through the use of this device, which not only increases the comfort and productivity of workers but also ensures work safety. By ensuring proper lighting in various zones of the factory, such as production areas, warehouses, laboratories, safety routes, etc,. with the help of lux meters, dark corners or risk zones are reduced and the chances of accidents are significantly reduced.

Environmental Control and Safe Working Environment

Air condition monitoring is an essential part of today's modern factory. If temperature, humidity, airflow, carbon dioxide, VOC, filter performance, etc. are not controlled, it directly affects the production quality and the health of workers. There are many industrial processes where the quality of the product is affected if a specific temperature and humidity is not maintained. For example, air quality is a major issue in industries such as food processing, pharmaceuticals, electronics, etc.

For this reason, modern Air conditioning monitoring Systems are installed in factories these days, which collect real-time data through digital se

Advanced monitoring systems give warning signals as soon as these irregularities are detected and automatically activate environmental control systems. As a result, it is possible to always maintain a safe, healthy, and quality production environment inside the factory. This reduces employee illness and the risk of accidents and equipment damage, thereby improving the safety standards of the factory as a whole.

In an industrial factory, digital electrical measuring devices are not only a tool for diagnosing mechanical faults, but they are also the key to safe, effective, and profitable production. If the above devices are used daily, the lives of the workers are protected, as well as the production system runs uninterrupted. In the current era where technology is advancing rapidly, the time a need to ensure the safety, efficiency, and cost-effectiveness of the factory by adopting digital electrical solutions.

Calibration

Calibration

HVAC/Clean Rooms

HVAC/Clean Rooms

Electrical

Electrical

Power & Energy

Power & Energy

Mechanical & Maintenance

Mechanical & Maintenance

Pharma, Health & Biomedical

Pharma, Health & Biomedical

Drone Solution

Drone Solution

Networking

Networking

Transformer & Relay Testing

Transformer & Relay Testing

Insulation, Resistance and Battery

Insulation, Resistance and Battery

Fault Testing & Diagnostics

Fault Testing & Diagnostics

Lightning Protection Solution

Lightning Protection Solution

Education, Research & Development

Education, Research & Development

Civil Equipment

Civil Equipment

Renewable Energy

Renewable Energy

Cleaning and supplies

Cleaning and supplies

Power Tools

Power Tools

Safety Tools

Safety Tools

Hardwares

Hardwares

Construction Supply

Construction Supply

Stationeries

Stationeries

Garden Tools

Garden Tools

Accessories

Accessories

Machines

Machines

Hand Tools

Hand Tools